Overview of Motion Platform Functionality

QUICK SUMMARY

-

The Northwestern Neuroscience and Robotics Lab needed a platform to manipulate soft robotic components in order to study their dynamic stiffness properties

-

The final product is a "Merlet" style parallel kinematic motion platform that moves with six Degrees of Freedom (DoF): x, y, z translations & roll, pitch, yaw rotations

-

As project manager, I led 5 other students with competency in mechanical, electrical, and software engineering to develop and integrate the platform's subsystems

-

As a mechanical engineer, I designed and machined the platform's linear actuators, baseplate, and linkages

-

There were 20 weeks between project initiation and final prototype delivery

-

$5100.97 was the final cost of the project, under the $5500 budget

-

This page mostly focuses on my mechanical design work; the actuators, joints, error analysis, and manufacturing strategy were my primary technical contributions

-

The project was done during Northwestern's Robot Design Studio course (this unique robotics class can be read about here)

BACKGROUND

The Project's Mission:

Empower Northwestern University's Neuroscience & Robotics Lab (NxR) to study variations in stiffness, damping, and fatigue properties of their novel soft robotic "fingertips" in all six degrees of freedom. The lab needs to establish an accurate relationship between the bent positions of a fingertip with the forces and torques they experience.

CAD model of a potential fingertip design

3D printed prototype with mounting holes

Translational and rotational degrees of freedom to be tested

NxR's Objective:

NxR's Current Testing:

In a typical manipulator (as shown below) force sensors are used as a feedback mechanism for controlling the grip of a hand. NxR wants to use the stress-strain relationship to develop novel robotic manipulators which infer forces based on the flexed position of a soft robotic fingertip. This could make manipulators easier to scale and simpler to implement.

To precisely describe the spring and damping constants of their materials, NxR used a 5 DoF platform to control position of test specimens. Yaw rotations and velocity control of the platform were important additions that my team needed to develop with our final solution.

Typical robot manipulator with ATI Nano 17 Force/Torque Sensor (source: ATI Youtube Page)

Test fingertip in current testing set-up. The force/ torque is recorded by an ATI Nano 17 on the bottom

Mechanical Design Requirements:

Below are the initial design requirements requested by NxR:

-

Provide a means of loading test specimens in 6 degrees of freedom

-

Exert ±20 N of force in each linear direction

-

Exert ±0.2 Nm of torque in each angular direction

-

-

Offer 10 mm range of linear platform motion (x, y, z)

-

Offer ±20° range of angular platform motion (pitch, yaw, roll):

-

Control position and velocity of the test specimen

-

Linear motions tracked with precision of 10 microns [~0.0004"]

-

Angular motions tracked with precision of 0.1°

-

The platform must move between opposite ends of the range in a 3 Hz cycle

-

-

Make it convenient for a single user to move the test equipment

Candid reflection on the requirements:

10 microns!!! A length equivalent to a single red blood cell diameter! If I could re-do this project, my single change would be to push back on this precision requirement sooner. With the project's limited time and budget, the analysis devoted to achieving that precision detracted from developing the platform's overall robustness. Furthermore, NxR wouldn't even benefit from this precision because their test specimens are rubbery 3d printed thermoplastics. A 10cm length of their rubbery fingertip materials expands by over 10 microns under an ambient temperature changes of a single degree Celsius! When prompted by this mid-way through the project, the sponsor agreed it was an excessive requirement. Precision within 100 microns (0.1 mm) was set as the new target for good data acquisition. Today I can appreciate the extra knowledge I gained while attempting to achieve 10 micron positioning precision; however at the time it was a big struggle. That stress gave me an appreciation for the saying, "If you're going through hell, keep going."

DEVELOPMENT PROCESS

Initial Research:

The team researched examples of academic and commercial motion platform products to understand the range of possible designs. Different platform architectures were compared before settling on the "Merlet" style, where linear actuators can be mounted rigidly while minimizing necessary motion in the joints.

Stewart-Style platform;

actuators adjust linkage lengths to facilitate motion

Quanser-Style platform;

actuators parallel to the platform move fixed length linkages

Merlet-Style platform;

actuators perpendicular to the platform move linkages

The above gifs were generated from content at PI USA and Quanser, two suppliers of hexpod platforms. Unfortunately, the lab could not afford any of their existing solutions. Manipulators which could meet this projects requirements all cost above $50,000 (some reach into the six figure range). Fortunately for them, college students work free!

Notice each architecture we considered uses actuators mounted in parallel to produce the desired motion. Using serial actuators (like a typical robotic arm) is impractical for several reasons; most significant is error accumulation along the open kinematic chain.

Initial Mock-ups:

With rough ideas in mind, I made some mock-ups to achieve the following:

-

Establish rough sizes for the platform's mechanical elements

-

Communicate progress and design direction to project stakeholders

-

Provide hardware (the right image) with a motor and optical linear encoder, so that:

-

the software team could start developing and testing closed loop motor control

- the electronics team could test and iterate circuit designs for custom PCBs

-

Mock-up of the merlet platform

Linear actuator with optical encoder

Mock-up construction details:

On a shoestring budget that would need to cover high cost actuator and sensing components in the final product, I made these mock-ups mostly from scrap materials found in the Segal Fabrication Lab where I worked.

With my limited time (I was simultaneously involved with this quadrotor and this rocket payload throughout this project) I used a laser cutter to quickly cut the platform components and segments for universal joints from scrap plywood, acrylic, and ABS. Holes for the joint fasteners were made with a drill press.

I modified a spare linear stage from the project sponsor to provide hardware for software and electronic testing. The stage used a stepper motor in open loop control. Closing the feedback loop was important to control the platform's accuracy. I bought this optical encoder as a stand-in sensor while the team deliberated on the final mechanism for sensing platform position. This optical encoder operates by passing over a thin tape with many tiny dashes that interrupt light, signaling incremental changes in position.

Difficulty with optical encoder:

The optical encoder tape was very tricky to mount due to its flimsy nature and tight position needs (pictured below). The manufacturer did not have specific recommendations for achieving the necessary alignment, which prompted some creative thinking. I laser cut a line into a piece of acrylic and held the tape in the laser's kerf. The taper of the kerf provided a convenient grip on the tape (for the unfamiliar, lasers cannot cut perfectly square edges, they cut a "V" shape; the taper depends on the focusing depth of the laser). Then I milled a slot to hold the acrylic in the stage's base. After adding a few washers to dial the spacing in, the encoder was finally able to read accurately!

Drawing of Encoder Tape Alignment Dimensions (from USdigital.com)

Component Selection:

The essential mechanical elements of the platform are:

-

6 parallel linear actuator units

-

6 fixed length linkages which connect each actuator to a single end effector

-

12 joints, which allow rotational freedom on the ends of each linkage

-

A force-torque sensor

-

A mounting device for holding test specimens

Simple enough, right? For a class with a 20 week timeline, the first 12 weeks were allocated to design, mock-up, and component selection. The last 8 weeks were dedicated to executing the project by building and testing the various systems. The mounts for the force-torque sensor and test specimens were designed by the team's other mechanical engineer, so I won't discuss those challenges here. I analyzed and built the actuators, linkages, and joints which are the focus of the rest of this section.

Joint Selection:

The degrees of freedom which exist in a chain of kinematic elements are commonly described by the Chebychev–Grübler–Kutzbach criterion:

M = 6 * (n-1) - 5 * j1 - 4 * j2 - 3 * j3

-

M: mobility, the number of degrees of freedom

-

n: number of linkages in the kinematic chain

-

j1: number of joints which allow 1 degree of freedom

-

j2: number of joints which allow 2 degrees of freedom

-

j3: number of joints which allow 3 degrees of freedom

-

Technically the equation should also consider joints constraining 4-5 degrees of freedom, but those are not relevant to the present discussion

-

Overview of joint degrees of freedom from ohio.edu

The platform topology necessitated:

-

n = 14 (the base, 6 actuator points, 6 fixed links, a top platform)

-

j1 = 6 (the linear actuators contribute 6 prismatic joints)

Universal joints alone would be insufficient for 6 DoF motion:

if j2 = 12, M = 0 [ 6*(14-1)-5*6-4*12 = 0 ]

Thus, at least 6 universal joints (j2) and 6 spherical joints (j3) are necessary for a 6 DoF Merlet-Style Platform:

if j2 = 6 and j3 = 6, M = 6 [ 6*(14-1)- 5*6- 4*6 - 3*6 = 6 ]

Ideal joints move in only rotational DoF (left)

Real joints have slop in translation DoF (right)

The joints I created for the mockup were universal joints with input shafts able to revolve like a plain bearing for the 3rd DoF; however, the slop and possible wear in plain bearings precludes them from being effective in the final product. Joint slop and backlash are significant when dealing with sub millimeter motion.

If time and budget allowed, these Hephaist spherical rolling joints would have less than 2.5 microns of slop. At 310$ per joint (which would total 32% of the project budget for only 6 joints!) and a 6 week lead time, they were not feasible for this project.

Instead, I found a set of pre-loaded universal joints on McMasterCarr and small radial ball bearings which could fit inside to create a 3 DOF joint for 60$. Concept CAD is shown to the right with the bearing highlighted in green. A single sample was purchased to see if the slop would be manageable. It was not; with a dial indicator, I measured axial play of ~.005" (100 microns) under small loads (my hand's gentle pushes) in the universal joint alone. On a lighter note, handling the tiny 0.25" outer diameter bearing was absurdly fun.

Undeterred, I dove into several technical papers on precision joints to identify a more suitable solution. This research from MIT's precision engineering department led me to consider a magnetic joint. I found tapped ferromagnetic 440C stainless steel balls with diametral tolerances of 0.0001" (~.003 mm) and paired them with cylindrical magnets held by internal retaining ring to create joints which cost a palatable 40$ per unit.

12 spherical joints satisfy the Chebychev–Grübler–Kutzbach criterion and leave some redundancy which effectively expands the workspace accessible by the end effector.

j3 = 12, M = 12 [ 6*(14-1)- 5*6- 4*0 - 3*12 = 12 ]

A tiny bearing in a universal joint enables 3 DoF motion

Magnetic balls functioned as spherical joints

Top: Schematic of the final joint interface between the linkage, magnetic ball, and actuator

Bottom: The physical mating parts of the final joint (linkage on the left, actuator carriage in center & right)

This solution provided 2 very appealing advantages for the final product. First, it increased the range of joint operating angles, making ~60 degree joint angles feasible. The universal joints were limited to 30 degrees, which would have constrained the manipulation space. Second, the limited force of magnetic attraction provided a safety feature; the ATI force torque sensor (which costs the lab ~6000$) would be protected from excessive compressive loads in the event of erroneous platform commands because the magnet would simply release the linkage.

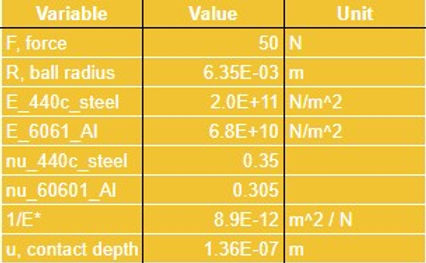

While still targeting 10 micron precision, I briefly read up on contact mechanics to estimate if deformation at the contact surface could induce undesirable play (this University of Arizona document provides a nice overview). I used a common equation representative of contact between a sphere and plane for my estimate. Since the contact between the ball and conical countersinks would likely distribute stress more than a theoretical ball on plane, this seemed to be a conservative approach. The resulting value of 0.1 microns (1.36*10^-7 m) was encouraging.

University of Arizona resource which describes contact stress

Table of values used for indentation calculation

Once the parts were manufactured and assembled, I was unable to detect significant play with a dial indicator set-up similar to my earlier evaluation of universal joints. At that time, the looser requirements obviated further study of play at the micron level (which would have required significantly higher fidelity measurement equipment).

Linkage Design:

The linkages were much simpler to analyze. Each link connected 2 joints and supported the platform. Their lengths were prescribed to be 130 mm by the teammate who created the kinematic solver for the project and optimized it for our workspace requirements. The worst case load condition would occur when only a single linkage moves to produced the desired platform position change. In this case the linkage would accelerate the mass of the entire platform and exert the required 20 N load on the test specimen. The platform mass was expected to be below 2 kg, so the total value of the worst case load was set at 50 N.

The basic deflection equation was used to solve for the necessary linkage radius which could sustain 50 N loads without exceeding 1 micron of deflection. As I will describe in the actuator design section below, the project could not directly measure the end effector position; thus potential position deviations between the end effector and actuator encoder had to fall under the target precision. For aluminum, this

set a minimum radius of 5.4 mm. For convenience of ordering materials, this was upsized to 6.35mm (the radius of a 1/2" diameter rod) . The deflection limitation led me to also examine the linear thermal expansion of the linkages; heat from actuators and variable ambient conditions were likely to cause undesirable position changes. Thus I computed what allowable temperature change could occur during a specimen test without reducing confidence in the estimated position.

The temperature values are degrees Celsius. This calculation led me to initially select titanium as the linkage material. Later in the project, while consulting with my teammate about mounting the lab's test specimens, I realized no matter how precise our platform was, the soft plastic materials being tested would not be dimensionally stable to within 10 microns! The graph at the right shows the expansion coefficients for the elastomer materials considered by the lab. When I prompted the client about this, the precision requirement was cut back to 100 microns. This enabled convenient design adjustments, like swapping the linkage material back to aluminum, which is considerably easier to machine than titanium.

The materials tested could not be held to high precision in nominal lab conditions

Functional Prototype:

To prevent a bottleneck in the project's software development while final components were shipped, I made an early prototype which could be controlled in 6 degrees of freedom. I relied again on laser cut acrylic as the fastest way to get hardware. The process was helpful to identifying flaws in the supporting mechanical elements and the device assembly process. The first function prototype had:

-

Six actuator units in a spacious configuration with maximum workspace for testing

-

Precision Linear Slide from THK to limit play in actuator movement

-

Optical encoder from the initial mock-up was integrated into a new actuator (in the video below, it is the actuator in the center with a white block)

-

-

Simple gasket based ball joints from McMaster Carr

-

Version 1 of custom motor control printed circuit boards (PCBs)

-

Laser cut acrylic structural components

Functional Prototype Testing

Above: Early model of the custom linear actuator

Right: Early motion platform CAD assembly

Prototype Refinement:

-

Actuators consolidated into 3 pairs of 2

-

Simpler manufacturing and assembly

-

Increases rigidity

-

-

Tested magnetic ball joints

-

Optimized length of linkages

-

Final dimensions of major components

-

Defined mounting locations for electronics

-

Magnetic linear encoders for feedback control

-

Version 2 of motor control PCBs

Above: The refined prototype

Fabricating the Final Product:

-

Maintained tolerances up to 0.001" for key actuator geometries

-

Actuator plates mounted with 0.005" perpendicularity

-

CNC Mill established key geometries

-

Laser cut acrylic enclosure for the power supply

Above: Render of the linear actuator units

Left: Render of the full assembly

Top Left: Validating the NX CAM tool-paths for manufacturing the base and movement plates

Top Right: Freshly fabricated base and movement plates

Right: Granite plate setup used to inspect key dimensions

Bottom Left: Acrylic enclosure for the power supply

FINAL FEATURES

Custom Linear Actuators:

-

Moons Nema 17 stepper motor with integrated leadscrew

-

THK ER616+100L precision linear slide

-

Helix Linear Systems anti-backlash nut

-

Safety limit switches at top and bottom of travel range

-

CNC machined aluminum housing

-

Custom motor control PCBs connected by CAN to master control unit

Left: The finished paired-actuator unit. 3 of these pairs created the desired 6 dof movement

Right: THK slide which constrained actuator movement in the plane perpendicular to the axis of travel

Left: Specs for the anti-backlash nut, the red boxes denote most significant performance values

Right: The motor's performance, the red dot is the operating point (11.2 lbf = 50 N, 5 in/s = 127 mm/s)

Left: The "carriage" of the actuator which connects the most critical components

Right: Schematic of "carriage" connections to linear slide, magnetic encoder, limit switches, and linkages

Magnetic Spherical Joints:

-

Sourced ferromagnetic 440C stainless steel balls with a 1/4-20 hole

-

Counter sunk holes in carriage and linkage to locate the ball

-

1/4-20 Bolt to secure in place

-

Magnet held inside linkage by retaining ring provides attractive force

ARTURAS'S RESPONSIBILITIES

Mechanical Engineer :

-

Designed linear actuators, ensuring speed and force needs were satisfied

-

Created SOLIDWORKS assemblies and actuator part models for each design iteration

-

Analyzed stress induced deformations in critical components

-

Used laser cutter, water jet cutter, and handtools to mock-up and iterate mechanical design elements

-

Used NX 12 CAM environment to plan CNC operations

-

Operated CNC mill for majority of platform fabrication

Project Manager:

-

Planned project milestones

-

Set deadlines for subsystem deliverables

-

Delegated high level tasks to teammates

-

Tracked task progress in JIRA software

-

Established organizational standards for technical documents with Confluence software

-

Tracking cost and time estimates from suppliers

-

Kept stakeholders briefed on project progress and obstacles

-

Organized team bonding events that boosted morale and team cohesiveness

Note: This webpage primarily describes the platform's mechanical design, which was the focus of my technical contributions to the project. The whole project would not have been possible without my incredible teammates who did excellent work in optimizing the kinematic configuration of the device, creating motor control electronics, implementing CAN communication between components, designing a custom MATLAB app user interface, fabricating PCBs, and many other tasks. If you are interested in further details on those parts of the project, I would be happy to forward the full project documentation to you. I can be reached at malinaarturas@gmail.com.

The team is also extremely grateful to our class's instructors, Ron Worth and Bill Hunt, for their guidance throughout the process. They connected us to valuable resources and provided constructive criticism for many aspects of our design.